Professional Freezers

Technological advancements in refrigeration have revolutionized eating habits and food consumption by offering complete control over the cold chain, significantly extending food preservation times.

In this section, we present a wide range of professional equipment essential for storing, freezing, and refrigerating any type of food.

Discover the products best suited to your needs in the "cold line": professional refrigerators, blast chillers, freezers, and pizza counters.

The Professional Freezer and the Art of Cooling

The world of catering is a dynamic universe where the freshness of ingredients is the key to success. In this context, professional freezer cabinets play an essential role, and the models available on our portal are at the forefront of cooling technology. Let’s dive into the technical features that make the professional freezer an indispensable element in every professional kitchen.

Advanced Cooling Technology:

Professional freezers stand out due to their advanced cooling technology. Precise temperature control is a key factor, ensuring that every food item retains its original freshness. From ice cream to seafood, the versatility of these freezers makes them suitable for a wide range of culinary needs.

The rapid cooling system is another distinguishing feature, allowing the organoleptic properties of food to be preserved in record time. This is particularly crucial in a professional setting where speed is essential without compromising quality.

High-Quality Materials and Functional Design:

Durability is at the heart of professional freezer design. Made with materials suited to withstand the daily challenges of a demanding work environment, their internal layout is designed to maximize space and facilitate access to various ingredients, thereby optimizing operational efficiency.

Smart Control and Constant Monitoring:

Managing a freezer cabinet becomes incredibly straightforward thanks to the control provided by integrated digital panels. Operators can monitor and adjust settings at their discretion, ensuring precise control and optimal resource use. This feature translates into time and cost savings, which are critical in a professional context.

Considerations:

In conclusion, investing in a professional freezer means choosing products built to last. Cutting-edge technology, high-quality materials, and functional design converge to create a product that goes beyond mere food preservation, becoming an indispensable ally for every chef and food industry professional. In the ever-evolving world of gastronomy, the industrial freezer stands as one of the pillars of a kitchen where raw materials are impeccably preserved.

Energy Efficiency: How to Optimize Your Freezer’s Use

At the core of every professional kitchen, the pursuit of maximum efficiency is crucial to ensure a flawless and environmentally friendly workspace. Industrial freezers go beyond simple food preservation, offering a strategic combination of excellent performance and low energy consumption. Let’s explore how to optimize the use of industrial freezers to achieve maximum efficiency without compromising quality.

Energy-Saving Features:

One of the standout features of professional freezers is their energy-saving capabilities. From technology that dynamically adjusts motor power based on demand, to thermal insulation (coibentation) of internal walls, to the adoption of efficient, eco-friendly gases like the new R290, every detail is designed to maximize operational efficiency.

The use of high-efficiency compressors significantly reduces energy consumption without sacrificing cooling performance. This attention to detail not only helps reduce environmental impact but also translates into economic savings for operators.

Practical Tips for Optimal Use:

In addition to technical features, there are daily best practices that can enhance the optimization of a freezer cabinet. Advising operators to load the freezer evenly, avoiding overcrowding that could hinder cold air circulation within the compartment, is the first tip to keep in mind.

Accurately adjusting the temperature based on the type of food being stored and scheduling regular defrosting periods are other actions that can positively impact long-term energy efficiency.

Real-Time Monitoring:

The ability to monitor energy consumption in real-time through an integrated digital thermostat is a distinguishing feature of the latest generation of professional freezers. This constant monitoring allows operators to quickly identify any anomalies and make timely adjustments to maintain peak efficiency.

Considerations:

In conclusion, optimizing the use of a professional freezer is not just about energy savings—it’s an investment in the future of professional kitchens. With their combination of energy-saving features, practical tips, and real-time monitoring, freezers stand as pillars of sustainability in an industry that demands consistent performance.

Using these freezers is not only an act of efficiency but also a commitment to a professional kitchen rooted in responsibility and excellence.

The Cold Chain: Crucial for Food Safety

In the catering world, food safety is an absolute priority. The cold chain plays a vital role in preserving the freshness and quality of ingredients, ensuring that every dish served is not only delicious but also safe for consumption. In professional freezers, this philosophy is a defining characteristic. Let’s explore how these freezers contribute significantly to food safety.

Precise Temperature Control:

The cold chain begins with the accurate and consistent management of storage temperatures. This control is essential for preserving the organoleptic properties of food and preventing the proliferation of harmful bacteria.

The ability to maintain stable temperatures even under varying load conditions is a hallmark of these freezers, ensuring that food safety is never compromised, regardless of operational challenges.

Regulatory Compliance:

In the food industry, regulatory compliance is critical. All our professional freezers come with a CE Professional certification, aligning with current food safety regulations. Materials that meet the strictest standards, easily cleanable surfaces, and integrated safety systems are inherent features of these devices, ensuring that every operator can work in compliance with regulations.

Traceability and Monitoring:

Food safety doesn’t stop at preservation—it also involves traceability. Our catalog includes cutting-edge professional freezers capable of providing detailed temperature monitoring and generating reports that document every change. This traceability is a valuable ally for operators, allowing them to demonstrate compliance to regulatory authorities and quickly identify and resolve issues with timely alerts via Wi-Fi connectivity.

Staff Training:

Beyond the technical features of freezers, food safety also depends on staff training. Today, operators can easily access training programs that outline best practices for the proper use of professional freezers and safe food handling.

Considerations:

In conclusion, the cold chain is not just a concept—it’s a practice. Food safety is at the heart of every gastronomic activity, and the commitment to ensuring that every dish served is safe and fresh must be pursued in every aspect. Investing in a professional freezer with the latest technology is not only an investment in food quality but also in the safety and reputation of your business.

Choosing the Right Freezer for Your Business: A Practical Guide

Purchasing a professional freezer cabinet is a crucial decision for any catering business. The wide range of options available in our catalog can make this choice somewhat complex, but with a few simple considerations, you can identify the right freezer for your needs. In this guide, we’ll walk you through the key factors to consider step-by-step to ensure you make the right choice.

1. Define Your Specific Needs:

The first essential step is to fully understand your business’s needs. Assess the required storage volume, the types of food you plan to store, and any special features needed, such as temperature tracking. This initial understanding will help you narrow down the available options.

2. Size and Space Layout:

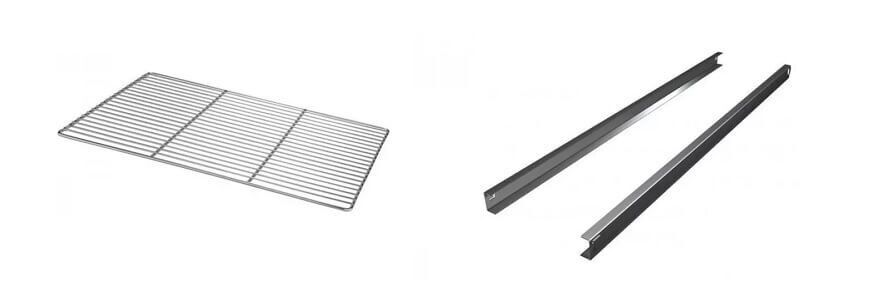

Accurately measure the space where the freezer will be placed. Ensure the chosen freezer’s dimensions fit seamlessly into your work environment. Also, consider the internal layout, evaluating whether a chest freezer or an upright model is better suited to facilitate access and food organization.

3. Energy Efficiency:

View energy efficiency as a long-term investment. A high-quality restaurant freezer offers advanced energy-saving features, such as high-efficiency compressors, enhanced thermal insulation, and high-performance eco-friendly gases.

These features not only reduce operating costs but also reflect your commitment to environmental sustainability.

To illustrate this, let’s compare the consumption (based on hypothetical values from February 2023, when this article was written) of two professional freezer cabinets—one outdated and one next-generation:

A) Class G Freezer (about 5 years old, to be replaced):

- Annual label consumption (AEC) = 4,000 kW

- Real usage consumption (+50%) = 6,000 kW

- Hypothetical current cost per kW = €0.48

- Hypothetical annual cost = €2,880.00

B) New Class C Freezer:

- Annual label consumption (AEC) = 1,818 kW

- Real usage consumption (+50%) = 2,727 kW

- Hypothetical current cost per kW = €0.48

- Hypothetical annual cost = €1,308.96

As you can see, the annual savings amount to €1,571.04.

In summary, carefully evaluate the following points:

- Energy class

- Climate class

- Daily consumption (kW)

- R290 gas

- Insulation material

- Potential tax incentives

4. Technical Features:

Examine the freezer’s technical specifications closely. Check the cooling capacity, adjustable temperature range, and the presence of specific features like ventilated cooling with automatic defrosting or IoT connectivity for remote monitoring. Technical features should always align with your business’s needs.

5. Drawer Freezers vs. Chest Freezers:

In the wide range of freezers, two types dominate: upright freezers and chest freezers. Both offer efficient storage solutions but have significant differences that need careful consideration.

- Upright Freezers:Characterized by their vertical structure with shelves or pull-out drawers, they provide clear and accessible food organization. This layout makes it easy to identify and reach ingredients quickly, making them ideal for kitchens with limited space where immediate access is essential. However, they may offer less overall capacity compared to chest freezers and might require more vertical space.

- Chest Freezers:These offer vast storage capacity in a box-shaped design with a single top opening. This layout maximizes internal space, making them ideal for freezing large quantities of food. However, internal organization can be more challenging than with drawers, and accessing specific items may take longer. Additionally, most chest freezers require more floor space, so the kitchen’s physical layout must be carefully considered.

In summary, the choice between an upright freezer and a chest freezer depends on your business’s specific needs. If convenience and organization are priorities, drawer freezers may be the ideal choice. If you prioritize maximum storage capacity and are willing to trade some organizational convenience, chest freezers could be the perfect solution.

6. Reliability and After-Sales Support:

Trust in the seller is crucial, especially when purchasing professional equipment. Positive reviews, ratings, and reliable customer support are excellent indicators of a worthwhile investment.

7. Budget:

Set a realistic budget for purchasing a professional freezer cabinet. Consider not only the initial cost but also long-term operating costs. A high-quality freezer may represent a significant investment, but the returns in operational efficiency and durability justify it.

Conclusions:

Choosing the right professional freezer requires a thoughtful and informed approach. With this practical guide, you’re now equipped to navigate the vast freezer market and make a choice that not only meets your business’s immediate needs but also contributes to long-term success. Remember that investing in the right products is an investment in the future of your professional kitchen.