-

Italiano

Italiano

-

English

English

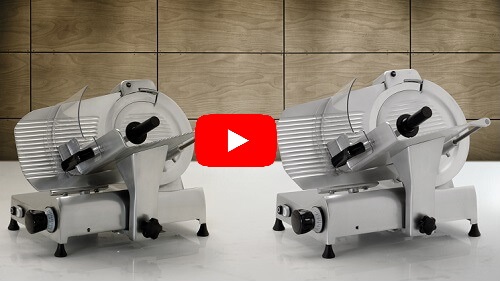

Professional slicer or meat slicer Fimar K370 37 cm blade

Slicer or meat slicer with Ø 370 mm blade, vertical, with visible carriage slides, for professional use.

Ideal for butcher shops, supermarkets.

Power: 370 watts.

New product

Buyable

Le immagini pubblicate hanno solo scopo illustrativo e non costituiscono elemento contrattuale.

Compare

Fimar professional vertical slicer with 37 cm blade

Slicer or meat slicer, vertical, suitable for professional use.

Frame made of anodized aluminum with shell casting.

Ventilated asynchronous motor with belt drive.

Removable blade guard.

Fixed blade protection ring.

Cutting thickness adjustment knob with graduated scale.

Fixed blade sharpener with pair of grinders.

Product can be supplied with sausage plate or meat plate, select desired version in item option.

Available with 220v single-phase and 400v three-phase power supply, select desired version in item option.

Professional Slicer

Finding your way around the vast world of professional slic ers may hide some pitfalls, as a wide variety of models are available on the market.

Professional slicers differ from domestic ones in the type and quality of materials and components used in their construction.

First, the material from which they are constructed: frame, carriage, plate and meat press arm are aluminum or specific anodized alloys.

In addition, the motors installed in professional versions are oversized and ventilated in order to ensure continuous work over time without loss of performance due to overheating.

The blade of the professional slicer are concave and forged and can easily reach sizes as large as 35 or 37 cm in diameter.

Let us try at this point to start simplifying.

The main categories of slicers are:

- Gravity slicers

- Vertical slicer

- Flywheel slicer

- Meat slicer

Professional gravity slicers

Professional gravity slicers are a cost-effective option for any business that needs a simple machine capable of cutting mainly cold cuts and cheeses.

Because the carriage is tilted toward the blade, the product tends to descend naturally (due to the force of gravity) toward the blade itself, making slicing operations easier and more convenient.

Professional vertical slicers

Professional vertical slicing machines are machines designed primarily for grocery stores or delicatessens or butcher stores, are capable of high performance.

In this type of machine, the weight of the product is loaded entirely on the slicer carriage, thus offering precise cutting and lower blade consumption. This type of professional slicing machine is particularly suitable for cutting large cold cuts, and slices of meat. Usually on the market are medium- and large-sized machines, with blades ranging from 30 cm up to 37 cm in diameter.

Flywheel slicers

Flywheel slicers, are manual versions that feature the same functions as electrified ones, but usually offer in addition a decidedly vintage aesthetic impact. In addition, these types of slicers ensure a precise cut without heating up the sausage.

The measurements that can be given to the cut by means of the adjustment knob range from a few millimeters (for example, for thin slices of ham) to even one or two centimeters (for cuts of meat).

Cleaning the slicer:

At the end of the day it is necessary to remove food scraps from the slicer, so as to eliminate the risk of fouling and especially the problem of bacterial growth. It is important to know that the product waste that accumulates in the various cuts is most frequently deposited in the inner areas of the blade guard, in the ware press and in all those areas that are difficult to reach from the 'outside. So how is it possible to clean the slicer?

Certainly in the first place it is necessary to unplug the machine to avoid unintentional switching on of the machine during the cleaning stages.

Next, the advice is to turn the slice thickness adjustment knob to the zero position so as not to risk accidentally bumping into the blade during cleaning.

Now, with a damp cloth, wipe the surfaces subject to movement to remove any residue that has formed; the same operation should be repeated on the side opposite the cut.

At this point we can remove the parafette bracket by loosening the specific screws for manual removal. This bracket has the task of preventing the slice from fitting into the rotation space of the blade. Remove the bracket, clean it thoroughly and reposition it.

Sharpening the blade

Over time we will begin to notice that to slice the machine will tend to require more pressure force against the blade forcing us to also increase the thickness of the slice to get a good cut. This means that it is time to sharpen the blade of our professional slicer.

Let's see how to do it:

A self-respecting professional slicer usually has a sharpening block, consisting of two small circular grinding wheels.

The sharpening block is positioned at the top of the blade arranged in such a way that it does not impede normal work activity.

To use it, it is necessary to rotate the sharpening block 180° and lock it with the fixing knob. Then it will be sufficient to press the two buttons that bring the grinding wheels closer to the blade to start the blade sharpening procedure.

FAQ - Frequently asked questions

The main questions to consider when choosing a professional slicer are:

Based on the product I need to slice which slicer should I choose?

Professional gravity slicers are a cost-effective option for any business that needs a simple machine capable of slicing primarily meats and cheeses.

Vertical slicers are machines designed for grocery stores, delicatessens or butcher stores and are capable of high performance.

Flywheel slicers, are manual versions that ensure precise cutting without heating the sausage.

They make a typically Vintage aesthetic impact.

What is the useful cut I expect from the machine?

Slicers equipped with the same blade diameter can offer significantly different lengths of cut called "useful cut." This is because the size of the cut also depends on the travel (or stroke) of the carriage and not just the size of the blade..

What is the maximum footprint?

Care must be taken when evaluating the overall dimensions of a slicer because it is often overlooked that the food carriage when the machine is working usually protrudes outside the frame outline. For this reason, it is important to take this into account when arranging the spaces in which to place the slicer.

View Blog guide: Professional slicer buying guide

| Width (cm) | Eighty two |

| Depth (cm) | Sixty five |

| Height (cm) | Sixty four |

| Net weight (kg) | Forty six |

| Power (kW) | 0,37 |

| Power supply | Power of choice |

| Color | Anodized aluminum |

| Typology | Vertical |

| Blade diameter (mm) | Three hundred seventy |

| Trolley stroke (mm) | Two hundred ninety |

| Cutting thickness mm | 0-15 |

| Support base (mm) | 660x540 |

| Useful cut (mm) | 290x275 |

| Sharpener | You |

| Sail block for CE models | No |

Send a message

Professional slicer or meat slicer Fimar K370 37 cm blade

Customers who bought this product also bought:

-

Fimar PPN25 three-phase 25 kg benchtop...

Professional countertop potato peeler. Capable...

€ 1.566,20

-

€ 15,00

-

Rotary ToasterFimar EST-A-3

EST-A3 Professional stainless steel rotary...

€ 457,06

-

Professional Meat Mincer Grater Fimar 12T...

Matched professional meat grinder grater 12T...

€ 573,46

-

Stainless steel basket for pasta cooker...

Stainless steel basket for pasta cooker...

€ 81,97

-

Professional pasta cooker 30 lt Fimar CPM30...

CPM/30 Professional electric pasta cooker with...

€ 1.982,23